- Sublimation/Textile Printers

- >

- Mimaki Dye Sublimation Printers

- >

- Mimaki TS330-1600 Printer

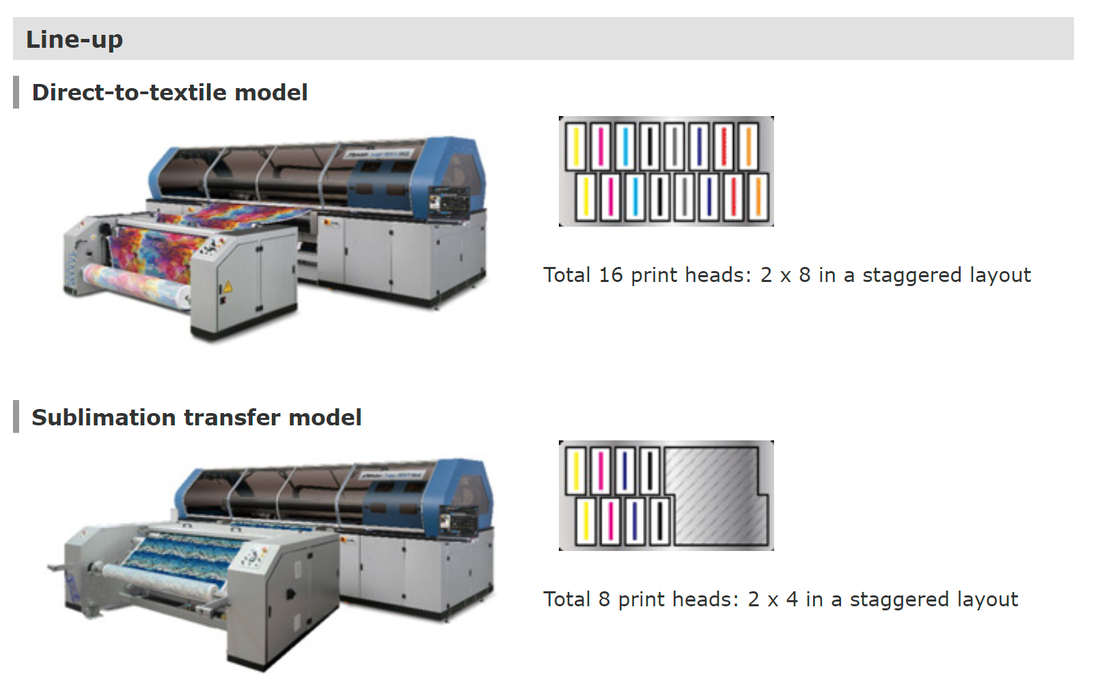

Mimaki TS330-1600 Printer

SKU:

$27,995.00

$25,195.00

$25,195.00

Unavailable

per item

PROMOTION INCLUDES:

- RasterLink7 Software Included

CALL US FOR PRICE

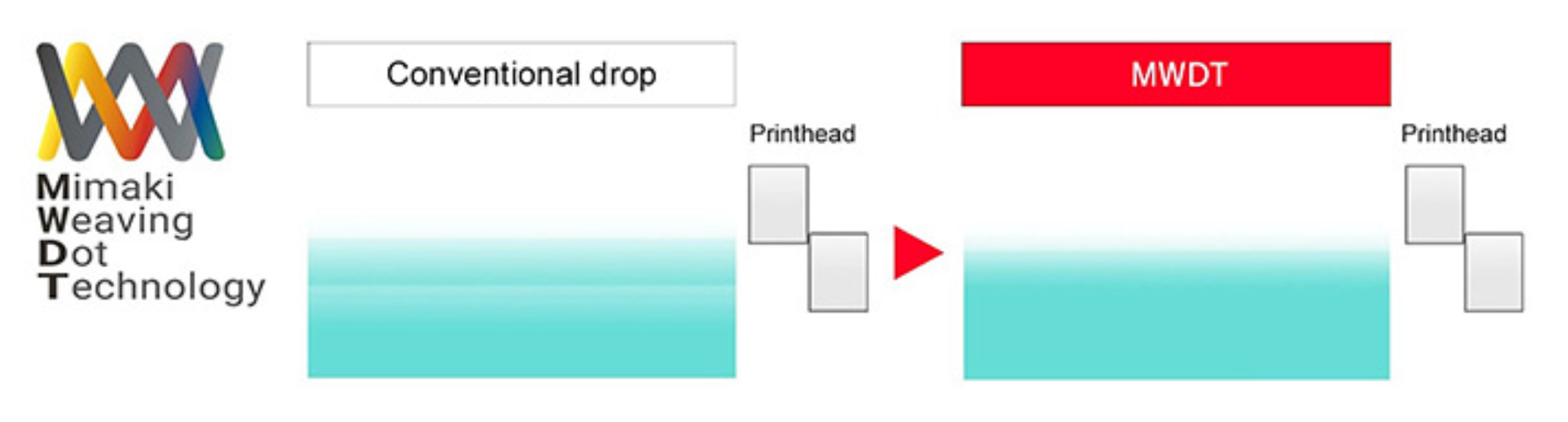

- Features:Mimaki Weaving Dot Technology(MWDT)- New technology realizing high image quality

- Improved production performance with high image quality

- Two options for lower running costs in production

- New functions to ensure reliable long hour print operation

- New maintenance mechanism for improved usability

- Mimaki Remote Access (MRA) enables operation status check and panel operation from a remote location

- Compatible with Mimaki’s two types of original RIP software to ensure beautiful prints and ease of use

| ts330-1600_brochure_usa.pdf | |

| File Size: | 1155 kb |

| File Type: | |

A new drop technology "Mimaki Weaving Dot Technology" expressing high-quality images suppresses an impact on printing caused by the individual difference of the head and misalignment in stagger adjustment and optimizes firing order, thereby realizing more accurate ink landing.

This makes it possible to reproduce deep colors vividly without unevenness and realizes beautiful print quality.

This makes it possible to reproduce deep colors vividly without unevenness and realizes beautiful print quality.

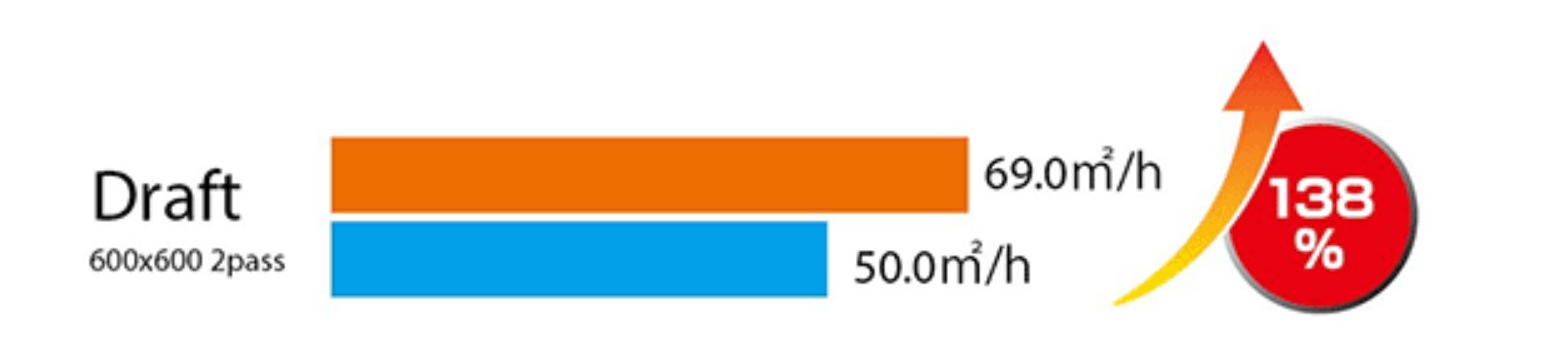

A wide range of print modes are available to suit your work, from the fastest mode of 135m²/h, to Draft mode of 69m²/h, and to High Quality mode of 21m²/h. In Draft mode, it achieves about 138% productivity compared to our conventional machine (TS55-1800).

When outputting a 1200 x 2400 mm sized print, the number of printed pieces per hour has been improved from approximately 13 to 18 pcs., which will be able to meet the market needs for high production.

When outputting a 1200 x 2400 mm sized print, the number of printed pieces per hour has been improved from approximately 13 to 18 pcs., which will be able to meet the market needs for high production.

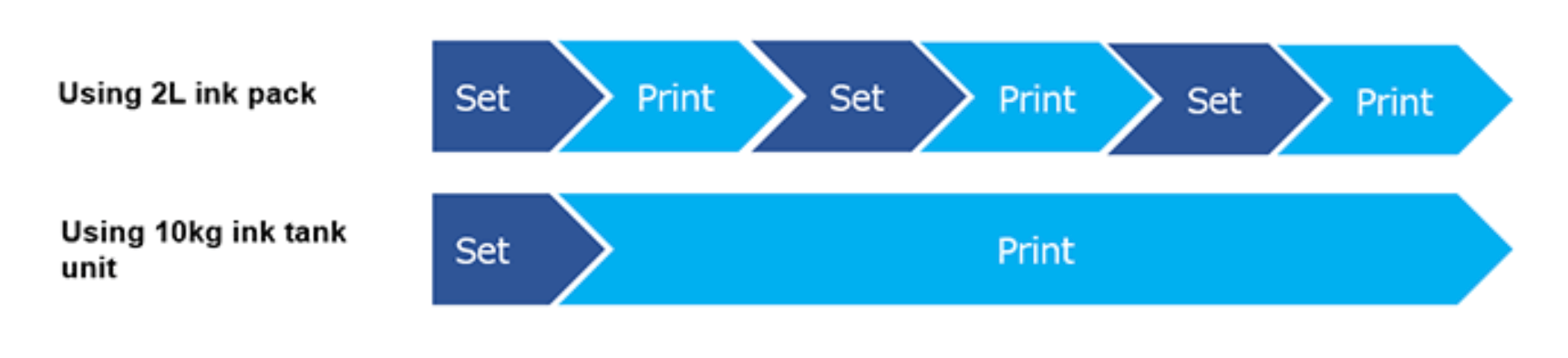

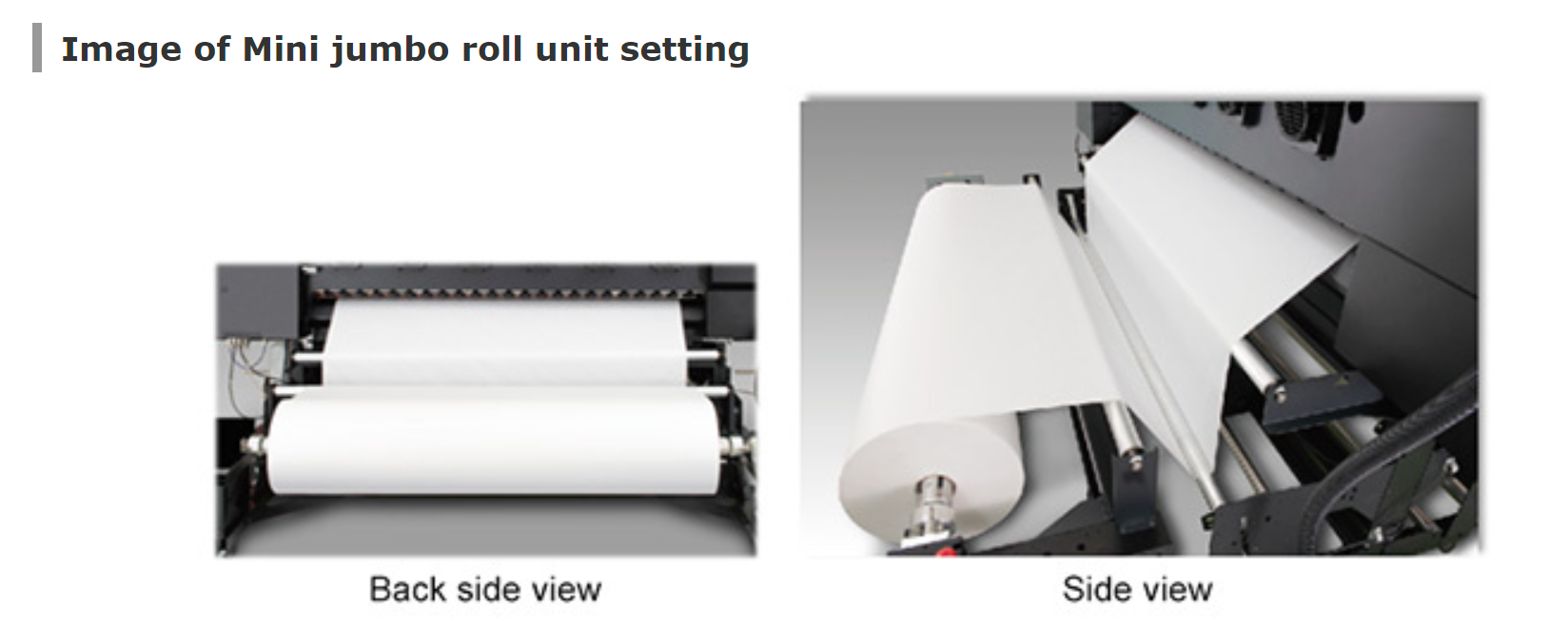

The "10kg ink tank supply unit" and the "Mini jumbo roll unit" are two options that can be used to reduce production costs.

The 10kg ink tank supply unit reduces the cost per cc compared to a standard 2L ink pack. The capability of continuous printing for a long time helps to reduce machine downtime, too.

The "Mini jumbo roll unit" can be used to load long transfer paper, further minimizing running costs.

The 10kg ink tank supply unit reduces the cost per cc compared to a standard 2L ink pack. The capability of continuous printing for a long time helps to reduce machine downtime, too.

The "Mini jumbo roll unit" can be used to load long transfer paper, further minimizing running costs.